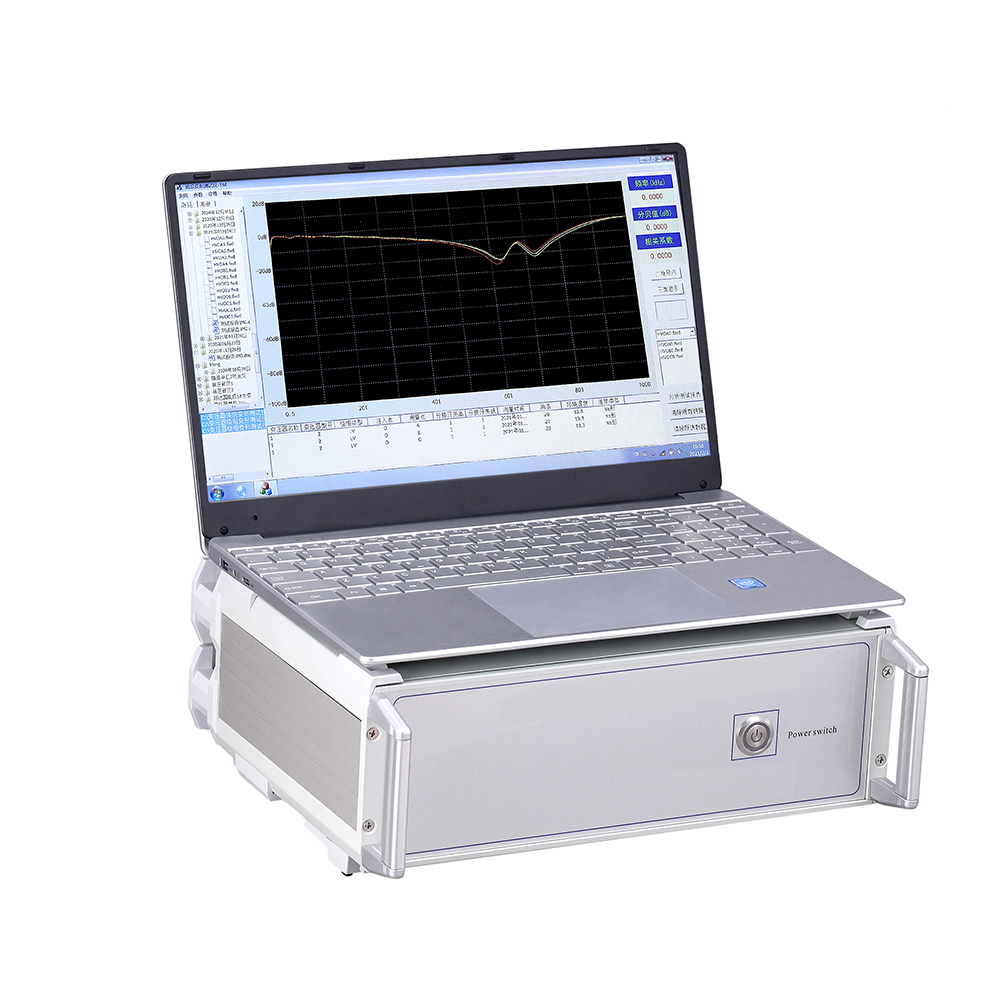

The UHV power professional production transformer winding deformation tester can help many power workers conduct various power tests more conveniently.

1、The hazards of transformer winding deformation

The deformation of transformer windings is a major hidden danger to the safe operation of transformers. The actual test results of multiple transformers show that it is difficult to detect the deformation of transformer windings in oil and insulation tests. This is a potential malfunction that is usually difficult to detect.

According to the report of the committee attending the 12th International Conference on Power Grids, there have been multiple instances of insulation failure in transformer windings due to initial mechanical damage to the insulation. When a transformer is subjected to the impact of short-circuit fault current, although the winding will partially deform, it will not be immediately damaged, but there will still be certain hidden dangers. Therefore, the harm caused by winding deformation cannot be ignored.

Changes in insulation distance lead to insulation breakdown accidents

The increase or decrease of insulation distance will cause certain damage to solid insulation, leading to partial discharge. If a thunderstorm happens to occur, there is a very high probability of cake breakdown and turn to turn phenomenon when lightning overvoltage is applied. Large scale and sudden insulation accidents may occur, and more seriously, even under normal operating voltage, insulation breakdown accidents may occur due to long-term operation of partial discharge.

Transformer winding deformation affects the normal operation of the entire power grid

The deformation of transformer windings has a significant impact on the entire power grid. It is related to the safe operation of the entire power grid. At the same time, when the transformer winding deforms, it will also bring about changes to people's normal lives. For example, when the mechanical performance of transformer windings decreases and a short circuit accident occurs, the windings will be unable to withstand the huge electromotive force, causing certain accidents and bringing continuous changes to the operation of the entire power grid and people's normal lives.

Therefore, it is necessary to strengthen the diagnosis of transformer winding deformation, timely detect deformed transformer windings, and carry out maintenance according to regulations to prevent a series of unpreventable accidents caused by winding deformation, while also saving manpower and material resources.

Accumulated effects, significant hidden dangers, and great harm

According to the normal operation experience of transformers, once the transformer winding deforms, a cumulative effect will occur, creating a vicious cycle effect. What is cumulative effect? For example, a 110kV, 31.5MVA transformer, after 6 years of operation, experiences multiple strong current surges on the 10kV side. After inspection, it was found that the transformer winding had undergone severe deformation. If the deformation problem is not detected in a timely manner, it is difficult to determine the time of the transformer accident. For example, after a month of operation of a certain transformer, the special gas in the oil rapidly increased, and after maintenance, it was found that the entire 35kV winding was deformed and scrapped. So,

Therefore, in some so-called "lightning strikes" or "sudden" accidents, there may be hidden factors of winding deformation and failure.

Measures to prevent transformer winding deformation

At present, transformers are the core equipment in the entire power grid transmission system. Transformer deformation diagnosis has been put on the agenda by countries around the world. Some countries attach great importance to it, and even include transformer winding deformation in the preventive testing of transformers. The primary position. For example, in the "Twenty five Key Requirements for Preventing Major Accidents in Power Production", the winding deformation test has been clearly included as a prescribed test item for transformers after short-circuit accidents and at the time of delivery.

Firstly, when designing transformers, various possible problems should be fully considered to design high-quality and long-life transformers. One of them must be limited to the short-circuit resistance of the winding. For transformer users, it is essential to choose transformers with strong short-circuit resistance. Long service life reduces the possibility of accidents.

2、 When handing over or inspecting the lifting cover, focus on checking the fasteners and transformer clamps. The current developed and implemented winding deformation testing technology allows transformers to continue operating even after being impacted. Timely maintenance can shorten the maintenance cycle and save manpower and material resources.

The transformer winding deformation test shall meet the following requirements:

Transformers with a voltage level of 35kV or below should use the low-voltage short-circuit impedance method;

Transformers with voltage levels of 266kV and above should use frequency response method to measure the winding characteristic diagram.