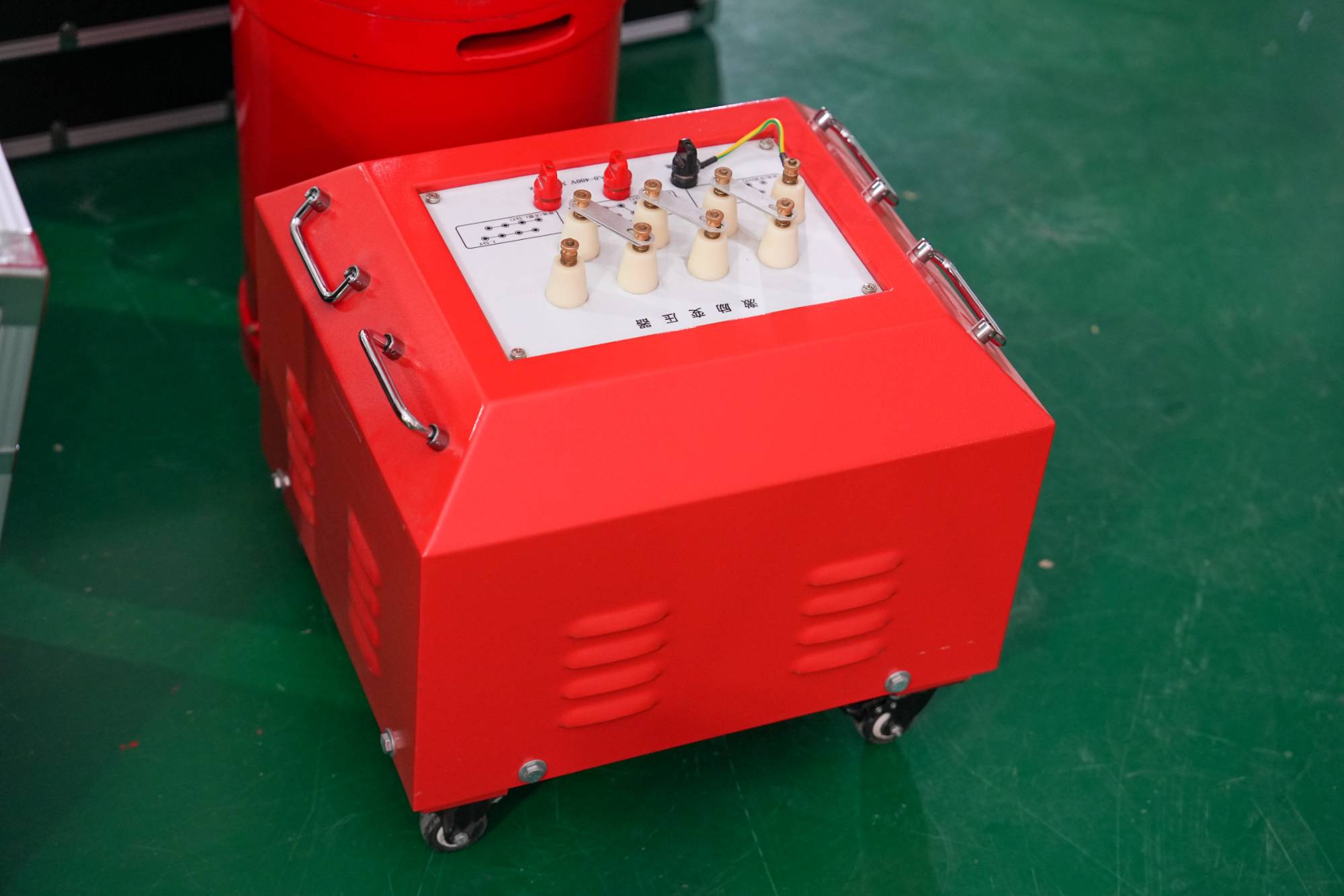

In the testing and application of power systems and electronic equipment, series resonant devices are a key testing device that can provide the required resonant frequency and voltage. Proper operation and maintenance are crucial to ensure the stability and accuracy of the device. This article aims to provide a detailed guide on how to correctly operate and maintain the device to help users improve its performance and extend its service life.

Preparation before operation is an essential step. Operators need to be familiar with the working principle, performance indicators, and operating procedures of the equipment. In addition, check if the device is intact and ensure that all connecting parts are securely fastened without any looseness. Before conducting experiments or tests, ensure that all safety measures are in place, including wearing appropriate protective equipment.

When operating the device, the principle of gradually increasing the voltage should be followed. Adjust to a lower voltage level first, then gradually increase to the desired value. This process should be carried out slowly to avoid sudden impact on the circuit. During the adjustment process, operators should continuously monitor the response of the equipment to ensure that it operates within its normal working range.

Maintaining the series resonant device is equally important. Regular cleaning and inspection are essential. The surface and internal components of the device should be kept clean to prevent dust and impurities from affecting electrical performance. Wipe the outer shell with a clean soft cloth and use compressed air to remove dust from the internal components. At the same time, check all wires and connectors for signs of wear or damage, and replace them promptly if necessary.

Avoiding overload and overheating is crucial during the use of the device. Overloading may not only cause equipment damage, but also lead to safety accidents. The working temperature of the monitoring device ensures that the cooling system (such as fans or cooling channels) is working properly, which can effectively prevent overheating. If abnormal temperature rise is found in the equipment, it should be stopped immediately for inspection.

Regular performance testing is a part of maintenance work. Check the output waveform and frequency of the device through professional testing equipment to ensure compliance with technical specifications. If deviations are found, relevant components should be adjusted or repaired. In addition, recording the results of each maintenance and inspection can help track changes in equipment performance and predict potential failures.

Proper operation and maintenance of the series resonant device are crucial for ensuring its stability and extending its service life. By following the above guidelines, users can reduce the risk of equipment failure and ensure the accuracy of testing and experimentation. Remember, prevention is always more economical and safe than dealing with it afterwards.